Leak detection and modern industrial production, maintenance, scientific research and other fields are inseparable, the traditional leak detection bubble leak detection (Bubble Test), differential pressure leak detection, etc., but these methods have many limitations and shortcomings, such as poor precision, low efficiency, etc.. Helium Leak Test (Helium Leak Test), as an internationally recognized leak testing method with high accuracy, has been widely used in the vacuum field.

The tracer gas of helium mass spectrometer can also be other elements, but helium is usually chosen because helium has the following characteristics:

① The content of helium in the air is small, accounting for only about one part in two hundred thousand, so that the background value of helium is small, which is conducive to the discovery of trace amounts of helium;

② Helium molecules are small, light, easy to diffuse, easy to cross the leakage hole, easy to detect and easy to remove;

(iii) Helium ions have a small charge-to-mass ratio, which is easy to analyze by mass spectrometry;

Helium is an inert gas, chemically stable and will not corrode or damage any equipment;

⑤ Helium is environmentally friendly, non-condensable and difficult to tolerate in water.

1. Vacuum Leak Test / Spraying Test (Vacuum Test: Spraying Test)

1)Can locate the leakage point

2)High accuracy

3)Low helium consumption

◎ Vacuum Leak Detection is a long time used in the industry, widely used in precision instruments, vacuum brazing, pressure vessels and other industries.

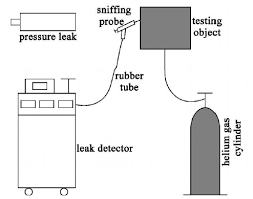

2. Sniffing Test

1)Can locate the leakage point

2)No need to vacuum

Suction gun method is widely used in power plant leakage detection, aerospace rocket gas control system leakage detection, etc.

3. Vacuum cumulative leak detection (Integral Vacuum Test)

1)Higher precision

2)Measure the overall leakage

3)Easy to detect online

4)High repeatability

◎ Vacuum cumulative leakage testing is suitable for leakage detection of fire fighting equipment cylinders, etc.

4. Back pressure method (Vacuum Test: Bombing Test)

1)Specified testing method for sealing devices

2)High repeatability

◎Back pressure method is commonly used in electronic components leak detection, etc.

5. Vacuum accumulation method (Integral test of enclosed parts under vacuum)

1)Easy automated testing

2)Higher precision

3)High repeatability

6. atmospheric pressure suction gun accumulation method (Sniffing test: Integral test at atmospheric pressure)

1)Easy on-line testing

2)No vacuum required

The atmospheric pressure sniffing test is widely used in aerospace industry.