The basic principle of helium detection for water-cooled panels

- Injection of helium: Inject helium into the equipment or system being tested, usually using a helium inflation system for control and monitoring.

- water-cooled panels: water-cooled panels are placed around the equipment or system to be inspected. The water-cooled panels have a heat dissipation function and control the temperature and propagation of the helium.

- Detection probe: A helium detection probe is mounted on the water-cooled plate, usually using cold-trap technology, where the helium gas is cooled and collected.

- Helium Detection Instrument: A device connected to the helium detection probe to detect and measure the adsorbed helium.

Advantages of helium detection of water-cooled panels

- High sensitivity: Water-cooled panel helium detection technology is very sensitive to hydrogen leaks and can detect small leaks.

- Fast: Water-cooled plate helium detection technology responds quickly to hydrogen leaks and can detect leaks in a short period of time.

- Non-Invasive: Water-cooled panel helium detection is a non-invasive method that does not affect the equipment or system being tested.

- Intuitive: Water-cooled panel helium detection technology visualizes the extent of a hydrogen leak by displaying the helium concentration.

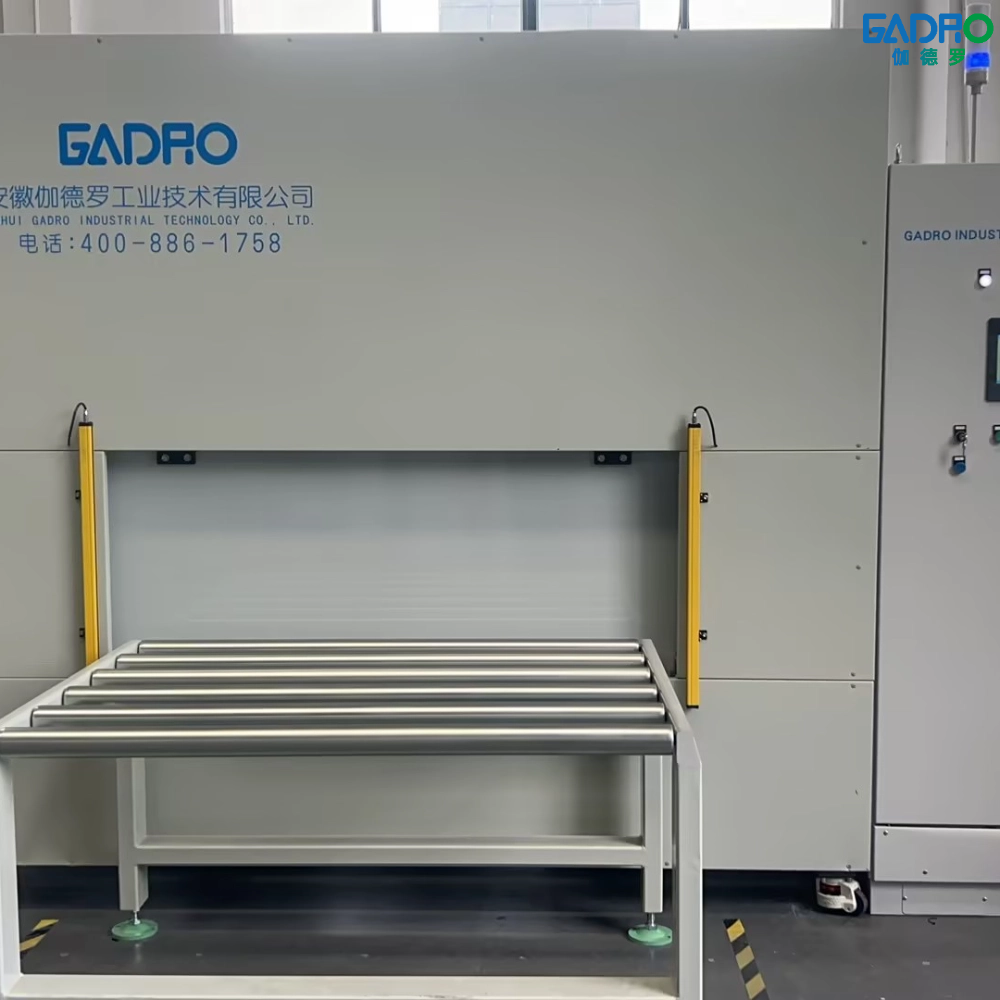

Equipment available for customized projects

- Helium pressure(MPa)

- Helium recovery or not

- Production rhythm (seconds/piece)

- Number of vacuum tanks

- Vacuum box rhythm (seconds/tank)

- Leakage rate requirement

- Net dimension of vacuum chamber

- Helium filling method for workpiece:Filling helium in the box/External helium filling

- Vacuum box switching door mode:Drawer type/Pulling type/Oblique pulling type/Duckbill type/Left-right translation/Or designed by the supplier

- Workpiece in and out of vacuum tank:Manual/Automatic

- Is it installed on the production line

- Equipment Placement Floor

- Outlet Pipe Position requirement

- Number of operators

- Layout requirements

- Other Requirements