In pressure vessels, there are three common methods of leak detection using helium mass spectrometry, i.e., the helium spray method (negative pressure method), the suction gun method (positive pressure method), and the helium mask method. In terms of the sensitivity of these methods, the helium injection method is more sensitive. However, when the leak detector is installed in a large, complex pressure vessel device, do not dare to say that the sensitivity of the helium spray method is high.

(I) Helium Spray Method

Helium spraying method is a commonly used and convenient method of leak detection. Leak detection, connected to the helium-filled cylinder on the gun to the suspected leakage parts of the helium spray, if there is helium from the leakage holes into the pressure vessel device, the helium partial pressure within the device will rise, helium leak detector on the display of the leak rate. Whether qualified depends on the standard leakage rate value is set at how much, more than the standard leakage rate value can be regarded as unqualified.

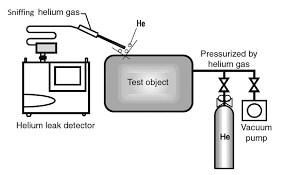

(ii) Suction gun method

Suction gun method is to fill more than one atmosphere of helium or helium and other gas mixture into the pressure vessel device, from the outside of the pressure vessel device to detect the leakage of helium from the leakage hole to the outside, and then find the leakage hole. When searching for helium with a suction gun, the helium leak detector displays a leak rate value once the helium has been inhaled. In this case, since the pressure vessel unit is at one atmosphere outside, the gas pressure filled into the pressure vessel unit needs to be at least one atmosphere or more. However, the pressure should not be too high, the pressure is too high, inserted in the device on the pressure gauge or other plug-in will be popped out and injuries and other dangerous accidents.

(iii) Helium hood method

This method uses a leakage detection cover (plastic film, etc.) to wrap the inspected container, first exclude the air inside the cover, and then filled with helium or helium gas mixture, the leak detector is connected to the inside of the inspected container, when the leak detector has a leakage rate is shown, it means that there is a leak. This leak rate is called the total leak rate. The total leakage rate is the sum of each sub-leakage rate; if the total leakage rate is not higher than the standard value, then each sub-leakage rate is not higher than the standard value; if the total leakage rate is higher than the standard value, then check whether the sub-leakage rate of each point is higher than the standard value. Then repair the leakage holes that are more than the standard value until it reaches the qualified standard.